Preparing for the unexpected should be a priority in inventory management.

Demand can rise without warning, shipments can get delayed, and you may run into some issues with your suppliers – all of which you have zero control over.

But where you do have control is in being prepared for this “unexpected” with a sufficient amount of safety stock.

In retail, this becomes a bit more tricky as trends and consumer behaviour change quickly and from one locality to another.

But with the right data and forecasting tools, you can tackle this issue, and avoid stockouts

This article will help you understand what safety stock is, why it matters, and how you can forecast the right level for each location so you’re always prepared, no matter what comes your way.

What is safety stock & why is it important?

Safety stock is the surplus stock or extra quantity of stock to prevent out-of-stock/line-down situations in your inventory.

This is a proactive approach to inventory management that acts as a backup to ensure you meet the local demand.

Typically, safety stock comes in handy in two situations:

- When demand exceeds your expected inventory levels

- When the replenishment lead time is longer than anticipated

Let’s see how it plays out in a typical scenario.

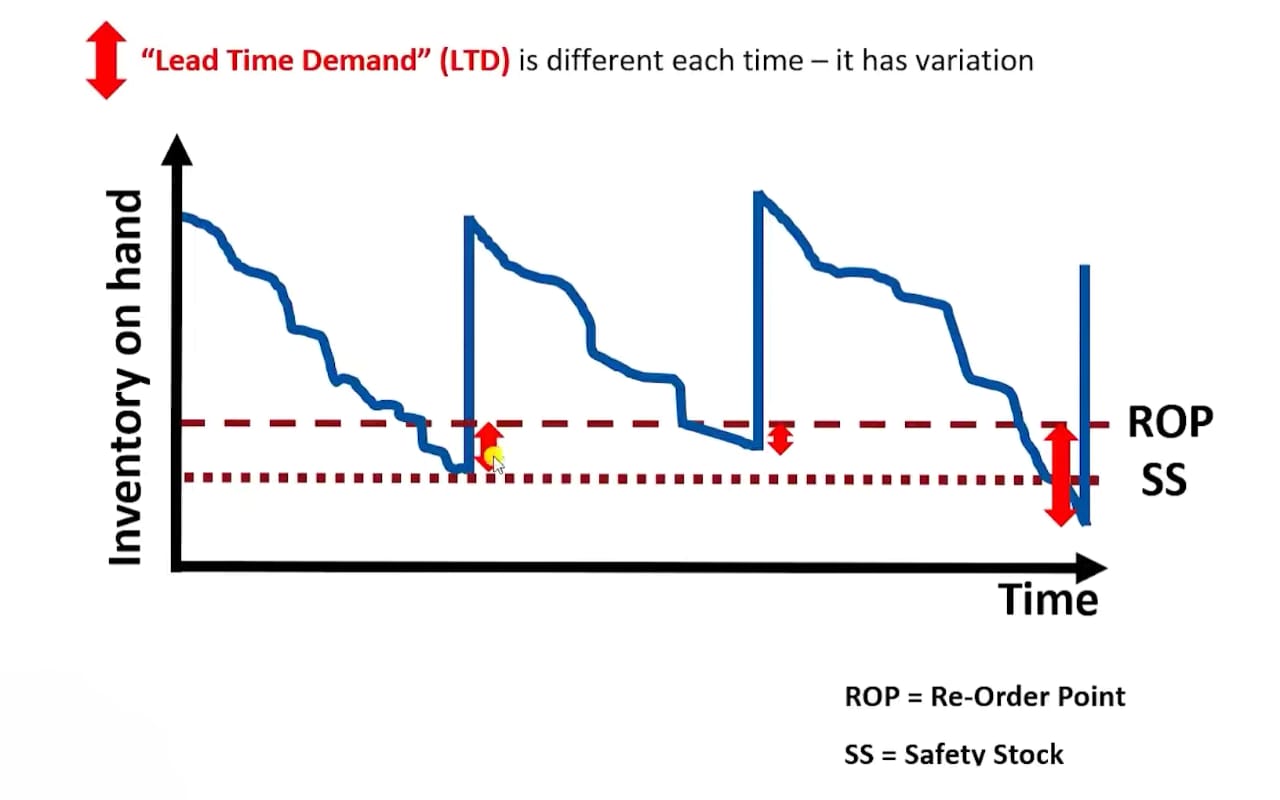

Image credit: Rowtons Training, YouTube

In the above illustration, we can see that when the inventory level (blue line) reaches the Reorder Point (ROP), you’re able to restock in time – without dipping into your safety stock.

However, when demand surges unexpectedly or the replenishment time is longer than anticipated (both of which can happen for various reasons), your inventory relies on safety stock to meet the local demand.

If you didn’t have safety stock at hand, you’re more likely to,

- Lose sales

- Disappoint or lose loyal customers

If you are trying to catch up while the demand is peak, you might also face increased shipping or emergency procurement costs.

How to calculate safety stock (with formula & examples)

Safety stock doesn’t have a one-size-fits-all formula.

The right calculation method depends on how much data you have, how variable your demand and supply are, and how risk-averse your business is.

No matter which method you choose, accurate demand forecasting is the foundation. Without it, you’re either overstocking (and wasting money) or risking stockouts (and losing sales).

We’ll get into how you can forecast demand effectively in a minute.

Below are three commonly used methods to calculate safety stock, along with examples to show how each works in a real-world scenario.

1. Max usage & max lead time method

This method plans for the worst-case scenario – when demand is at its highest and lead times are at their longest.

It could be used when you’re just starting out with inventory planning and want to build a cushion against unpredictability.

Formula:

Safety Stock = (Maximum daily usage × Maximum lead time) – (Average daily usage × Average lead time)

Example:

Let’s say your product’s maximum daily usage is 120 units, and the maximum lead time from your supplier is 10 days. On average, you sell 100 units per day, and your usual lead time is 7 days.

If we plug in these numbers, this is how the formula would look like:

Safety Stock = (120 × 10) – (100 × 7) = 1,200 – 700 = 500 units

So, you’d keep 500 units of safety stock to stay protected during demand spikes and supplier delays.

2. Average demand × lead time buffer

This method can be ideal if your demand is somehow relatively stable but lead time sometimes fluctuates slightly.

Formula:

Safety Stock = Average daily demand × Buffer in lead time (in days)

Example:

Let’s assume you sell 80 units per day on average, and your lead time can vary by up to 4 days.

If we plug those numbers into the formula, it’ll be:

Safety Stock = 80 × 4 = 320 units

So, you’d keep 320 units of safety stock to cover a 4-day delay and avoid stockouts.

3. Service level method (Z-score & demand volatility)

This method is for when you want to hit a target service level, meaning, how often you want to fulfil customer demand without running out of stock.

It uses:

- Z-score: A number tied to the service level you want to maintain (e.g., 95% = Z of 1.65).

- Standard deviation: The average range your demand fluctuates (basically, the volatility of your demand)

Formula:

Safety Stock = Z × Standard deviation of demand during lead time

Example:

Let’s assume you want a 95% satisfactory service level (95% Z is equal to 1.65), and your demand during the lead time fluctuates by about +/- 150 units.

Then the formula would be:

Safety Stock = 1.65 × 150 = 247.5 (round to 248 units)

Using this one, you’d keep 248 units of safety stock to confidently serve 95% of your customers even when demand varies.

So, how do you forecast demand accurately?

All the above methods rely on knowing your customer behaviour and demand patterns well.

The problem is once you have scaled or started to scale your retail, it becomes increasingly difficult to stay on top of trends and customer behaviour as it varies wildly from one store location to another.

Here’s where GeoIQ’s advanced analytics and ML models help you forecast demand accurately for safety stock with reliable data.

Our solution combines real-time external data (like footfall patterns, local market trends, customer spending capacity, behaviour, and more) with your internal sales history to create precise demand forecasts – down to the SKU level, for each store or warehouse.

Once you stock your inventory based on hyperlocal demand signals, you can stock the right amount to stock for the shelves as well as for the safety stock levels.

It also gives you the ability to:

- Identify which products to keep more of, and where

- Understand regional buying patterns before they become obvious

- Optimise safety stock for both fast-moving and long-tail SKUs

Also, retail demand forecasting reduces the risk of turning safety stocks into dead stocks.

Conclusion

Safety stock is your safety net. But only when it’s based on accurate demand insights.

Overstocking and stockouts can both hurt your business. With the right forecasting tools, you don’t have to fix one at the cost of the other.

Book a 15-minute demo with us to leverage real-time signals and optimise your inventory and safety stock levels, tailored for each store!