Stockouts frustrate customers and lead to lost sales, while excess inventory ties up capital and increases storage costs. So, striking the right inventory balance is one of retail’s biggest challenges.

Optimising replenishment is the simple answer for this ever-lasting challenge yet traditional methods often fail to keep up with fluctuating demand, seasonal trends, and localised preferences.

To tackle this issue, businesses nowadays are turning to data-driven approaches that leverage external data and AI along with the brand’s own data to improve demand forecasting and streamline inventory management at the store level for each SKU.

This guide discusses the key aspects of replenishment planning, its benefits, challenges, and how you could utilise advanced analytics for replenishment planning tailored at the store & product level.

What is replenishment planning?

Replenishment planning is the process of determining when and how much stock should be replenished to maintain optimal inventory levels.

This is the systematic approach to restocking inventory based on demand patterns, sales data, and supply chain constraints. Replenishment planning in retail aims to prevent stockouts and overstock situations by striking the right balance between supply and demand.

The process typically involves:

- Monitoring stock levels across various locations to ensure product availability.

- Analysing historical sales trends to predict future demand.

- Forecasting demand fluctuations to align inventory with market needs.

- Determining optimal reorder quantities to avoid excess inventory.

- Coordinating with suppliers to ensure timely restocking and smooth logistics.

Strategising an effective replenishment plan ensures that your store(s) do not lose sales due to stockouts while minimising excess inventory costs, which can impact your bottom line.

Benefits of replenishment planning

A well-executed replenishment planning strategy offers several advantages including the below:

1. Reduced stockouts and overstock

Stockouts lead to lost sales and customer dissatisfaction, whereas overstock results in higher carrying costs and potential markdown losses.

Having a great replenishment plan ensures products are available when needed without accumulating excessive inventory.

2. Optimised inventory management

Proper replenishment ensures a streamlined supply chain with minimal disruptions.

It also balances inventory levels across multiple locations to improve efficiency and avoid unnecessary storage costs.

3. Increased sales and revenue

An efficient replenishment strategy helps businesses meet customer demand without delays.

You can meet the expected sales consistently thanks to accurate demand planning with advanced ML models!

4. Improved customer satisfaction

When customers find what they need when they visit a store or shop online, it automatically improves brand loyalty and encourages repeat purchases.

5. Cost reduction

Minimises inventory holding costs and markdown (discount) losses by aligning replenishment with actual demand trends. Reducing excess stock also improves cash flow and operational efficiency.

6. Better supplier coordination

In the long term, efficient replenishment planning helps businesses maintain a steady supply flow and negotiate better deals with suppliers, improving procurement efficiency and lead time management.

Traditional vs Demand-driven replenishment planning

Historically, replenishment planning followed a fixed schedule or was based on anecdotal data which wouldn’t take current trends, location demographics, and other external factors into account.

However, modern retail businesses are moving towards demand-driven replenishment models that leverage data analytics and real-time insights.

Let’s break down this difference in short.

i) Traditional replenishment planning

Traditional replenishment planning often relies on static inventory thresholds and periodic restocking schedules.

It often lacks responsiveness to real-time demand fluctuations and market changes. The key characteristics include:

- Fixed reorder points – based on past sales trends.

- Limited flexibility in adjusting to sudden demand shifts.

- Reactive approach, where inventory is replenished only after reaching predefined thresholds.

- Higher risk of stockouts during demand spikes and overstock during slow periods.

ii) Demand-driven replenishment planning

Demand-driven replenishment planning uses advanced tools such as our location intelligence platform that utilises real-time data to optimise inventory levels dynamically.

The platform takes into account various external factors such as customer behaviour, seasonality, weather conditions, competitor presence, performance, etc.

Some key advantages of demand-backed replenishment planning include:

- Dynamic demand forecasts based on live sales data.

- Real-time adjustments to replenishment strategies.

- Higher flexibility in managing unexpected demand changes.

- Reduced risk of stock imbalances, ensuring better stock optimisation.

It’s clear that demand-driven replenishment planning ensures that businesses remain agile, responding to market shifts, customer preferences, external disruptions and other factors in near real-time.

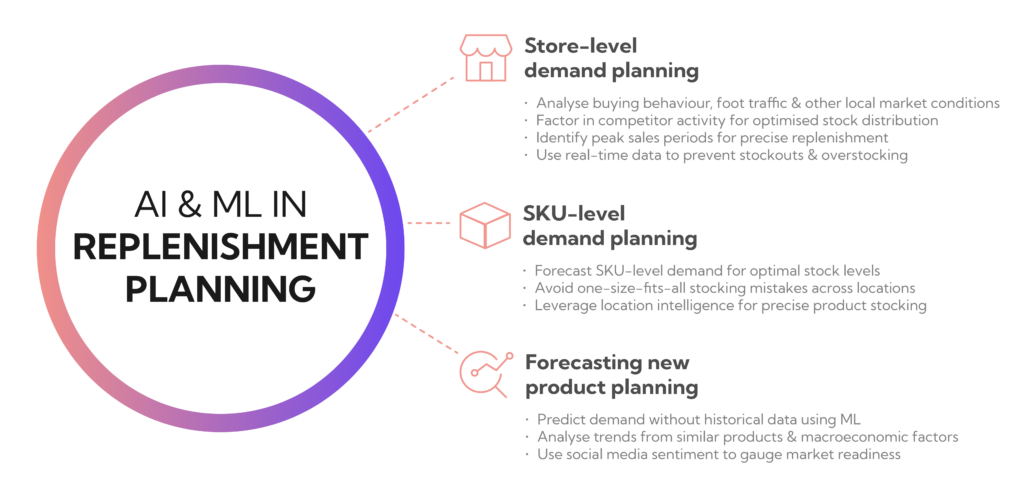

Utilising AI and ML models in replenishment planning

Modern replenishment planning should integrate location intelligence and machine learning models to improve the accuracy and efficiency of your inventory.

These advanced technologies help you predict demand at both the store level and product SKU level, even for new or yet-to-be-launched products!

i) Store-level demand planning

Store-level demand planning involves analysing store-specific sales trends, foot traffic patterns, and local market conditions to optimise inventory distribution.

Also, by using historical transaction data, businesses can identify peak sales periods and factor in the said factors and more to align replenishment schedules accordingly.

External factors such as competitor activity in your presence also play a crucial role in determining store-level demand.

For instance, opening a store next to a competitor can actually benefit your store but you should also predict sales and foot traffic after factoring in competitor analysis. The location intelligence platform takes all of these into account while aiding in replenishment planning.

By leveraging real-time data and predictive analytics, retailers can dynamically adjust stock levels across different locations to prevent stockouts and excess inventory.

ii) SKU-level demand planning

Similarly, you can forecast demand at product SKU level ensuring you stock the right stock levels for each item.

It’s easy to make a mistake while forecasting demand at the SKU level in a traditional method.

For example, you may stock an overwhelming amount of products thinking the product would sell, since it sells the same quantity at another location.

However, trends, buying patterns, and other demographic characteristics vary drastically from one location to another at the street level.

The ideal path to finding the best selling products at every location is to utilise a location intelligence platform.

iii) Forecasting demand for new products

One of the biggest challenges in replenishment planning is predicting demand for products without historical sales data.

Traditional forecasting methods struggle to provide reliable estimates since you would have minimal to no reliable data but machine learning models address this challenge by leveraging alternative data sources.

By analysing trends from similar product categories, monitoring macroeconomic indicators, and evaluating social media sentiment, you can generate demand forecasts for new product launches and how well they resonate with local markets across the country.

Conclusion

Granular-level replenishment planning is a necessity moving forward.

While traditional approaches rely on static rules, the adoption of demand-driven methodologies will adapt and improve your bottom line significantly.

Book a 15-minute demo with us to learn how our solutions can improve yours too!