Even the best retailers aren’t immune to miscalculating demand and overproducing products.

This has become a recurring phenomenon, especially in the fashion industry where the trends change dramatically with time and from one street to another.

In fact, around 12% of fabric produced globally gets wasted during the design process alone – adding up to over 2 billion pounds of waste every year.

So, what happens when products that do make it to the shelves miss the mark? They turn into dead stock – unsold inventory that sits idle, tying up capital and taking up space.

But dead stock is evitable. By using real-time trend analysis and accurate demand forecasting, you can prevent excess inventory before it ever becomes a problem.

This article explores how you can align your inventory with actual demand which ensures you eliminate dead stock and improve your bottom line.

What is dead stock?

Deadstock refers to inventory that has remained unsold for an extended period and is unlikely to sell in the future without significant intervention.

These items are essentially “dead” in warehouses or on store shelves, generating no return for your business.

There could be some instances where safety stock could become a dead stock. The reason however is simple: inaccurate demand forecasting and a poor understanding of local market preferences.

We’ll get into how you tackle these in the coming sections.

Dead stock vs. obsolete stock: Understanding the difference

You might confuse dead stock with obsolete as the same but there are some subtle differences:

Dead stock:

- Has never been sold since its acquisition

- Still functional and technically usable

- May have failed to sell due to poor demand, overestimation of market interest, or pricing issues

Examples: Clothing items that didn’t hit the mark with consumers or stocking excess products.

Obsolete stock:

- May have previously sold well but is now outdated

- Typically replaced by newer versions or technology

- No longer competitive in the current market

Examples: Last year’s electronics models, discontinued product lines, items with expired technology.

Though these two are slightly different, both problems result in financial liabilities. This article focuses primarily on dead stock, though many prevention strategies apply to both categories.

Causes of dead stock

To prevent dead stock accumulation, it is crucial to understand the root cause behind it.

Here are the primary mistakes that could lead to dead stock:

1. Inaccurate demand forecasting

The most common cause is poor demand forecasting which could lead you to order products in quantities that exceed actual customer demand.

This forecasting challenge is particularly acute for:

- New product launches with no sales history

- Seasonal items with narrow selling windows

- Trendy products with unpredictable lifecycles

2. Disconnection from market trends

You have to understand the overall local demographics and local market trends to know what to stock at the product SKU level.

As we know, the retail industry is a dynamic one, and businesses that fail to stay current risk accumulating dead stock. Below are some of the instances you should mitigate:

- Merchandise that doesn’t reflect current consumer preferences

- Products that missed timing with seasonal or cultural trends

- Items that don’t align with evolving customer values (e.g., sustainability, ethical production)

3. Ineffective pricing strategies

Pricing mistakes can quickly transform active inventory into dead stock.

Understanding what customers want, paired with local demographics such as avg. income of the household, buying behaviour, preferences, etc. in your catchment lets you price your products right.

All these 3 problems and more can be solved efficiently by utilising large external datasets and AI that give you an unfair advantage over the competitors!

We’ll get into detail in a minute.

4. Poor inventory management

Having inadequate or incapable inventory systems and processes contributes significantly to dead stock accumulation.

Without streamlined systems in place, stock-related decisions are often reactive rather than proactive – leading to missed signals and stockpiles of unsold products.

These gaps usually show up as:

- Lack of real-time visibility across sales channels

- Poor implementation of inventory management techniques

- Insufficient monitoring of slow-moving items

- Absence of early warning systems for declining product performance

5. Poor product quality or presentation

Often sometimes, the product your inventory boasts itself could be your problem in accumulating dead stock.

This stems from factors like frequent customer returns due to quality issues, inadequate product displays, poor merchandising, or unappealing and damaged packaging.

How to prevent dead stock in retail?

Preventing dead stock requires a multifaceted approach and it begins with understanding your local market demand better with data.

1. Utilise external datasets for accurate demand forecasting

For years retailers have relied on past sales data that may not work in the future as consumer expectations and local market trends change overnight.

To eliminate the risk of dead stock for good, it is high time to utilise large eternal datasets such as the below:

i) Demographics data

Understanding the specific customer characteristics in your catchment areas enables precise inventory planning.

Know the exact population, age, income levels, purchasing behaviour, education level & more to stock the right products in your store.

For example, if you’re a fashion retailer in a locality with a larger youngster population, your store may need higher quantities of trend-forward styles popular with Gen Z, while locations serving older demographics might require different cuts, styles, and comfort features.

| Related: GeoIQ identified affluent localities where premium products perform best – resulting in a 45% overall sales boost!

ii) Customer preferences & trends

Beyond demographics, understanding what customers actually prefer is essential for preventing dead stock.

Analysing social media engagement, shopping habits, and Google searches at the street level provides immense clarity on what customers actually want and what products you should procure in the right quantity.

These raw data paired with advanced AI and ML models can help forecast demand for products at SKU and street level.

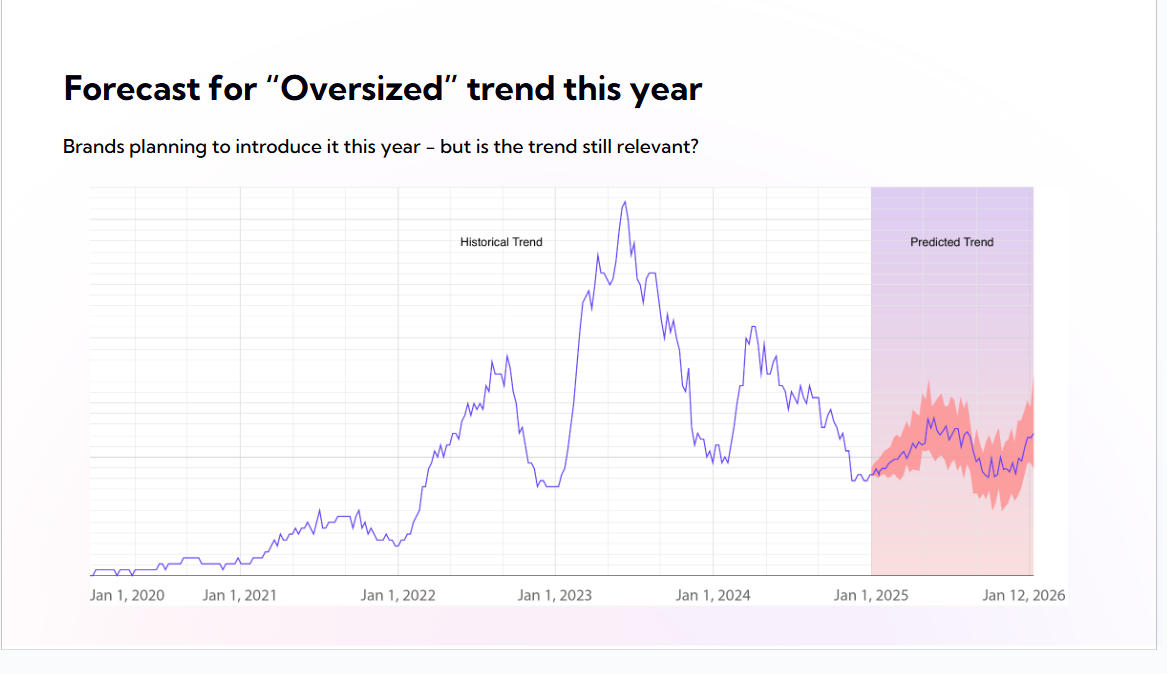

Below is one such projection our models have predicted for the oversized clothing trend in 2025 & beyond:

iii) Dynamic pricing

Static pricing strategies often fail to account for fluctuations in demand, competitor moves, or seasonal shifts – leading to either missed revenue opportunities or unsold inventory, aka, dead stock.

Adopting real-time trend analysis solves this by adjusting product prices in real-time based on market conditions, customer demand patterns, & purchasing power.

iv) Competitive context

The location landscape of your market dramatically influences product performance and varies significantly even within small geographic areas.

Being close to competitors can help but not all the time.

The catchment area you serve should have sufficient customer density to make sure the market hasn’t reached saturation. So, understanding the competitive and local landscape helps prevent over-ordering & dead stock.

2. Invest in inventory management systems

Today’s inventory management solutions provide powerful tools specifically designed to prevent dead stock:

A capable inventory management system is crucial for keeping dead stock under control. Investing in advanced inventory management software can help gain real-time visibility across all sales channels, accurate stock level monitoring, and automated alerts for slow-moving or excess inventory.

3. Product quality testing and customer feedback analysis

As we mentioned before, sometimes the products themselves could be your answer to solve the dead stock problem.

Ensure your procurement partner is reliable and check the quality of products every time you take them to the shelf.

By identifying product issues early, you can address problems before they result in warehouse shelves full of unsellable merchandise.

Also, ensure you collect and analyse customer reviews, returns data, and sales associate input to identify potential product issues early.

Repurposing dead stock

Despite best prevention efforts, some dead stock is inevitable.

Here are some strategic approaches to minimise the impact:

1. Creative remarketing

Sometimes, the dead stock simply needs a fresh presentation:

Repackaging: Present the product in a new way with updated packaging or positioning.

For this to happen you may want to check how your customers interact with the products that just sit on the shelves, whether they take a look at the product or just move past it.

In both cases, repackaging could be your best bet.

Bundling – Combine slow-moving items with popular products at attractive package prices.

This approach not only clears out dead stock but also incentivises customers to buy more.

For instance, bundling an underperforming accessory with a popular product at a discounted combo price makes the purchase feel like a better deal.

2. Liquidation channels

If the above creative strategies don’t clear your dead stock, you can consider external avenues.

Sell unsold inventory to off-price retailers, leverage online liquidation marketplaces, or partner with flash sale sites to quickly move products. Here, the goal is to recover part of the cost rather than full ROI.

3. Charitable donations

When recovery isn’t feasible, donating dead stock can still offer value. Contribute to local charities or international aid organisations. This will help gain goodwill while freeing up storage space and reducing costs associated with it.

4. Recycling

For stock that’s beyond salvage, sustainability should be the focus. Partner with recyclers to recover raw materials, or look at whether you can explore closed-loop programs to reintroduce materials back into your production cycle.

Conclusion

Dead stock is one of retail’s most persistent challenges, silently eroding profits and tying up resources that could drive your business growth by expanding your store presence.

With the data-driven approaches and strategic methods outlined in this guide, you can dramatically reduce your dead stock exposure.

The most successful retailers are now treating dead stock prevention as a core business function and you should too.

Schedule a 15-minute discovery call with us to know exactly what to stock, which stores it will perform well in, and in the right quantities, so you can minimise the risk of dead stock.